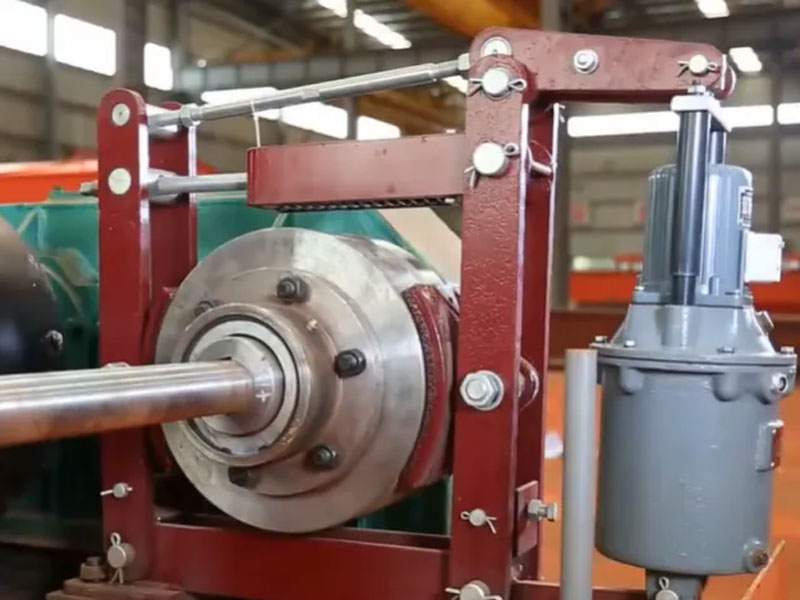

The brake system in a bridge crane is a critical component that ensures operational safety and precision. However, due to its frequent use and exposure to various working conditions, brake failures may occur. Below are the primary types of brake failures, their causes, and recommended actions.

Failure to Stop

When a brake fails to stop the overhead crane, the issue might stem from electrical components such as relays, contactors, or the power supply. Additionally, mechanical wear or damage to the brake itself could be responsible. In such cases, both the electrical and mechanical systems should be inspected to identify and resolve the issue promptly.

Failure to Release

A brake that does not release is often caused by mechanical component failure. For example, worn friction pads or a loose brake spring could prevent the brake from functioning correctly. Routine inspections of the brake system, particularly its mechanical parts, can help prevent this problem and ensure the equipment operates smoothly.

Abnormal Noise

Brakes may produce unusual noise after prolonged use or exposure to humid environments. This noise typically results from wear, corrosion, or inadequate lubrication. Regular maintenance, including cleaning and lubrication, is essential to avoid such issues and extend the brake’s service life.

Brake Damage

Severe brake damage, such as worn or burned gears, can render the brake inoperable. This type of damage often results from excessive loads, improper usage, or inadequate maintenance. Addressing these issues requires immediate replacement of damaged parts and a review of operational practices to prevent recurrence.

Importance of Timely Repairs

The brake system is crucial for the safe and efficient operation of a bridge crane. Any failure should be reported immediately to the appropriate personnel. Only qualified technicians should handle repairs to minimize risks and ensure compliance with safety standards. Preventive maintenance is key to mitigating brake-related problems, enhancing the equipment’s reliability, and reducing downtime.

Post time: Dec-24-2024