Product Details

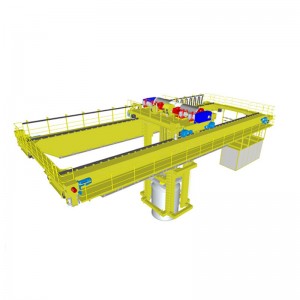

Ladle Handling Overhead Crane for Still Mill

-

Load capacity

5ton ~ 320ton

-

Crane span

10.5m ~ 31.5m

-

Lifting height

6m ~ 30m

-

Working duty

A7~A8

Overview

Overview

Ladle handling overhead crane is one type of metallurgy crane, which is designed for transporting, pouring and charging hot metal in the process of smelting liquid metal, etc.

According to the crane structure, the ladle overhead cranes can be classified into double girder double rail overhead travelling ladle cranes, four girder four rail overhead travelling ladle cranes, and four girder six rails overhead travelling ladle cranes. The front two types are used for lifting middle and large scale ladles, and the latter one is used for extremely large scale ladles. SEVENCRANE know the hazard and challenge of metals production industry and can offer customized ladle handling overhead crane as per client’s requirements.

A ladle handling crane lifts large, open-topped cylindrical containers (ladles) filled with liquid metal to the basic oxygen furnace (BOF) for mixing. The raw materials of iron ore and coking coal are combined to produce solid metallic iron, and this iron added to scrap metal creates steel. The crane also transports the liquid iron or steel from the BOF and electric arc furnace to the continuous casting machine.

Ladle handling crane is designed specifically for the extreme environment of heat, dust and hot metal in a melt shop. Therefore, it include features such as Increased working coefficients, a differential gear reducer, a backup brake on the rope drum, and motion limiters making the crane and application safe and reliable. It can also be used for teeming and casting.

Gallery

Advantages

Project Recommend

Related Products

Contact

If you have any questions, you are welcome to call and leave a message We are waiting for your contact 24 hours.

Inquire Now

Get Price

Get Price Contact Us

Contact Us Chat Online

Chat Online